Leave Your Message

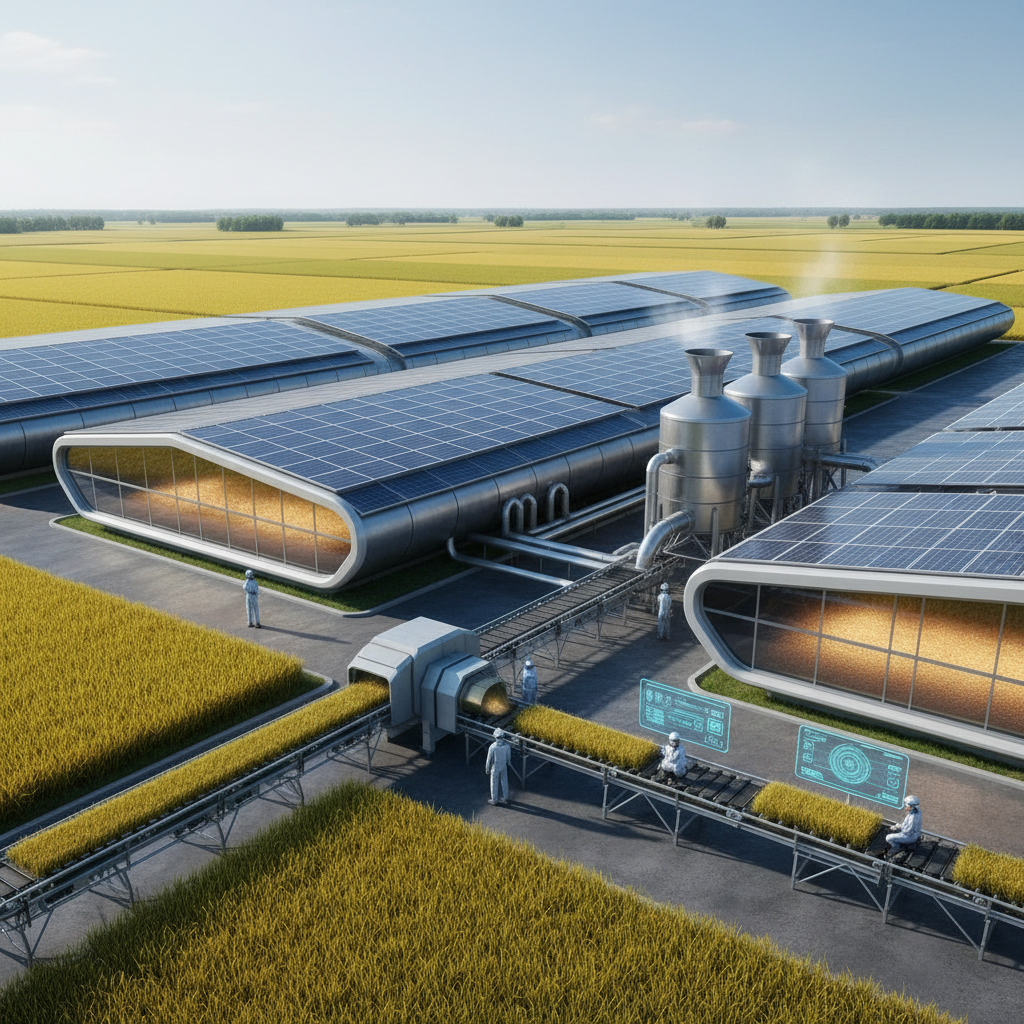

In an era where agricultural efficiency is paramount, the "Rice Dryer" industry is poised for groundbreaking innovations by 2025. According to a recent report by the International Rice Research Institute, improving drying processes can enhance grain quality and reduce post-harvest losses by up to 30%. These statistics underline the urgent need for advancements in rice drying technology, driving the industry toward solutions that minimize energy consumption while maximizing efficiency.

Industry expert Dr. Ellen Wang states, "The future of rice drying technology is not just about faster processes but also about sustainability and energy efficiency." Her insights reflect a growing consensus among agronomists that the integration of smart technologies and renewable energy sources in rice dryers will transform traditional methods. As we delve into the top innovations expected within the next few years, it is crucial to examine how these developments can provide farmers with effective grain drying solutions, ultimately improving their yields and economic viability.

The world of rice drying technology is evolving rapidly, driven by the need for more efficient grain drying solutions. Recent advancements have focused on integrating smart technology and automation into rice dryers, ensuring a seamless and energy-saving drying process. Key features like moisture sensors and real-time monitoring systems allow farmers to optimize drying conditions and minimize grain loss due to over-drying. These innovations not only enhance efficiency but also contribute to higher quality rice production.

**Tips for Choosing an Efficient Rice Dryer:**

When selecting a rice dryer, consider models with advanced moisture detection capabilities. These systems can significantly reduce energy consumption by adjusting drying time based on the actual moisture content of the grain. Additionally, look for dryers equipped with insulation materials that improve heat retention, as this can greatly boost efficiency.

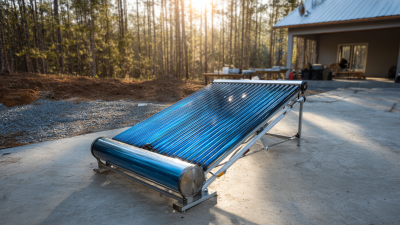

Another important feature to seek is the compatibility of the dryer with renewable energy sources. Solar-assisted rice dryers, for example, can provide eco-friendly drying solutions while reducing operational costs. Integrating such technologies aligns with sustainable agricultural practices, ensuring that rice production remains both efficient and environmentally responsible.

In recent years, the integration of IoT (Internet of Things) solutions in agriculture has transformed traditional grain drying processes. The advent of real-time monitoring and control in grain drying not only enhances efficiency but also minimizes waste. By utilizing smart sensors, farmers can now obtain accurate data on moisture levels, temperature, and energy consumption, allowing them to make informed decisions that directly impact grain quality and storage longevity.

**Tips:** When selecting an IoT solution for your grain drying system, consider platforms that offer user-friendly interfaces and comprehensive analytics. Ensure that the sensors are calibrated correctly to capture the most accurate readings, as this will enable you to fine-tune your drying process further.

Another innovation is the automation of grain dryers, which relies heavily on IoT capabilities. With automated systems, farmers can remotely monitor and adjust drying parameters through their mobile devices. This flexibility offers a significant advantage, especially during peak harvest periods when time and efficiency are crucial.

**Tips:** Invest in systems that provide alerts and notifications for any abnormalities in drying conditions. This proactive approach can prevent potential losses and optimize your grain drying strategy by allowing for immediate interventions when needed.

| Innovation Feature | Description | Efficiency Benefit | IoT Integration | Real-Time Monitoring |

|---|---|---|---|---|

| Dynamic Temperature Control | Adjusts drying temperature based on grain moisture levels | Reduces energy consumption by up to 30% | Sensors communicate with a central control system | Allows grain operators to access data remotely |

| Automated Moisture Detection | Monitors moisture levels in real-time | Minimizes over-drying and ensures optimal quality | Integrates with cloud-based platforms | Alerts users about moisture levels via mobile app |

| Energy Recovery Systems | Reuses heat from the drying process | Improves overall energy efficiency by 25% | Cloud connectivity for process optimization | Monitor energy savings and usage |

| Predictive Analytics | Utilizes machine learning for optimal drying schedules | Enhances drying efficiency and reduces waste | Data collected is used for predictive maintenance | Insights available on mobile dashboards |

| Remote Control Operation | Allows operators to control machines from anywhere | Reduces labor costs and enables flexibility | Smartphone application for control | Receive notifications for operational status |

The rice drying process is undergoing significant transformations, particularly as we approach 2025. With a pressing need for sustainable practices, innovations in energy-efficient technologies are paving the way for more eco-friendly drying solutions. These advancements not only help reduce energy consumption but also lower operational costs for farmers. By utilizing renewable energy sources such as solar and biomass, rice dryers are becoming more aligned with environmentally responsible practices.

Tips for maximizing energy efficiency in rice drying include regularly maintaining drying equipment to ensure optimal performance and reducing drying times through pre-drying techniques. Implementing sensor technologies can also help monitor moisture levels accurately, enabling better control over the drying process and preventing over-drying.

Moreover, integrating advanced drying technologies, such as heat pump dryers and electrohydrodynamic dryers, can significantly enhance efficiency. These innovative systems utilize less energy than traditional methods while providing consistent results. As the industry transitions toward sustainable practices, keeping abreast of these innovations will be crucial for rice producers looking to optimize their operations in a greener, more efficient manner.

As the agricultural industry continues to evolve, the need for efficient and user-friendly automation in grain drying processes has become increasingly vital for farmers. The innovations in rice dryer technology for 2025 are focused on simplifying operations and maximizing efficiency, allowing farmers to spend less time managing drying systems and more time on other critical aspects of their farming practices. With features such as intuitive control panels, real-time monitoring, and automated adjustments based on humidity and temperature, these advancements reduce the manual labor required and ensure optimal grain quality.

Moreover, incorporating technology like IoT and AI into rice dryers allows for seamless integration with farm management systems. Farmers can now monitor their drying process remotely, receiving alerts and data analytics directly to their smartphones or tablets. This level of automation not only enhances productivity but also empowers farmers to make informed decisions, ultimately leading to better yield management and cost efficiency. By prioritizing user-friendly designs, these innovations are set to revolutionize the grain drying landscape, ensuring that farmers are equipped with the tools they need to thrive in a competitive market.

This chart illustrates the efficiency improvements in various rice dryer innovations for the year 2025, emphasizing user-friendly automation and its impact on grain drying processes.

As grain drying techniques continue to evolve, a comparative analysis of traditional and modern methods reveals their respective advantages and disadvantages. Traditional drying techniques, such as sun drying and use of conventional dryers, offer low operational costs but may result in inconsistent moisture content and increased labor. In contrast, modern innovations, like infrared drying and hybrid drying techniques, provide enhanced efficiency and better preservation of grain quality, although they require higher initial investments and advanced technology.

Tips: When considering drying options for rice, evaluate the quality of the product, available resources, and investment capacity. Modern drying facilities can significantly reduce drying time while maintaining the nutritional integrity of the grains.

Additionally, emerging methods like the simultaneous use of convection and radiation heat transfer, as seen in studies on pistachio drying, show potential for application in rice drying as well. By adopting these innovative approaches, farmers can achieve optimal moisture levels rapidly, ultimately leading to improved yield and market competitiveness.

Tips: Stay informed about the latest drying technologies and explore local agricultural extension services for guidance on the best practices tailored to your specific context.