Leave Your Message

In the agricultural industry, selecting the right equipment is crucial for optimizing productivity and ensuring high-quality output. One such essential piece of equipment is the rice dryer, which plays a significant role in reducing moisture content and preserving the quality of harvested rice. As John Smith, a leading expert in agricultural technology, aptly stated, “The right rice dryer not only enhances the quality of your grain but also significantly reduces post-harvest losses.”

Understanding the various types and features of rice dryers is vital for farmers and producers aiming to make informed decisions tailored to their specific needs. With many options available on the market, from conventional to modern systems, the opportunity to invest in a rice dryer that maximizes efficiency while minimizing costs is greater than ever.

This article will explore essential tips for choosing the best rice dryer for your needs, guiding you through the critical factors to consider. By leveraging expert insights and industry knowledge, we aim to provide a comprehensive overview to help you select a rice dryer that best suits your operational requirements.

When selecting a rice dryer, it's crucial to understand the different types available, as each serves a unique function tailored to specific drying needs. The most common types are batch dryers, continuous flow dryers, and mobile dryers. Batch dryers allow for small to moderate amounts of rice to be dried in discrete loads, making them ideal for smaller farms or households. These dryers are often more economical and easier to operate, though they require more attention and manual handling.

Continuous flow dryers, on the other hand, are designed for larger operations that need to process significant quantities of rice quickly. They operate by continuously feeding rice into the dryer while simultaneously removing dried rice, ensuring a steady output. This type can be more complex but is efficient for commercial scale production. Mobile dryers provide flexibility, allowing users to transport the drying units to different locations. This can be particularly beneficial for farmers who deal with varying crop sizes or need to adapt to fluctuating market demands. Understanding these differences can help you make an informed decision that best suits your rice drying needs.

| Type of Rice Dryer | Capacity (kg) | Fuel Type | Efficiency (%) | Price Range ($) |

|---|---|---|---|---|

| Batch Dryer | 500 | Natural Gas | 85 | 3000 - 5000 |

| Continuous Dryer | 1000 | Electric | 90 | 7000 - 12000 |

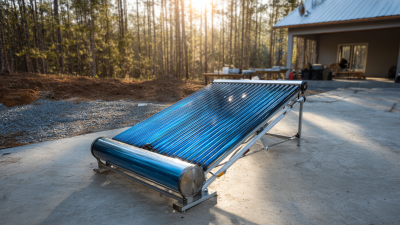

| Solar Dryer | 200 | Solar | 75 | 500 - 1500 |

| Hybrid Dryer | 800 | Electric + Biomass | 92 | 4000 - 8000 |

| Fluidized Bed Dryer | 600 | Natural Gas | 88 | 5000 - 9000 |

When selecting a rice dryer, it’s crucial to consider several key features to ensure you choose the best model for your needs. First, look at the drying capacity and efficiency. A rice dryer with a higher capacity can save you time and energy, making it suitable for larger farms or processing operations. Energy consumption is another vital factor; opting for a dryer that uses less energy can lead to significant cost savings over time.

Another important aspect is the technology used in the dryer. There are various drying methods available, such as hot air, infrared, and microwave drying. Each method has its advantages and disadvantages, so understanding your specific requirements can help you make the right choice. Additionally, consider the maintenance needs of the dryer. A model that is easy to clean and requires minimal maintenance will save you time and effort in the long run.

Lastly, don’t overlook the importance of safety features. Look for dryers that come equipped with temperature control systems and moisture sensors to prevent damage to the grains. By paying attention to these essential features, you’ll be well on your way to selecting a rice dryer that meets your operational needs efficiently.

This chart illustrates the importance level of various key features to consider when selecting the best rice dryer. Capacity and user reviews are among the most critical factors for making an informed purchase decision.

When selecting the ideal rice dryer, understanding your capacity requirements is paramount. According to a report by the Food and Agriculture Organization, the average farmer in Asia needs a drying capacity of at least 1.5 tons per hour to manage their post-harvest rice efficiently. This figure reflects the demand for timely processing; delays can lead to quality degradation and financial losses. Assessing your drying needs involves considering the volume of rice harvested during peak seasons and the frequency of drying cycles.

Moreover, the energy efficiency of the rice dryer plays a critical role in long-term operational costs. A study published by the International Journal of Agriculture and Biology highlights that dryers with a capacity of 2 tons per hour can reduce energy consumption by up to 30% compared to smaller models. When choosing a dryer, it’s essential to strike a balance between capacity and energy efficiency, ensuring the equipment can handle your harvest while maintaining economic viability.

Thus, calculating your actual drying requirements will help in selecting a rice dryer that suits your specific operational needs, ultimately enhancing productivity and profitability.

When selecting a rice dryer, energy efficiency should be a top priority. Rice drying processes can consume significant amounts of energy, impacting both operational costs and environmental sustainability. An energy-efficient rice dryer not only helps lower energy bills but also reduces the carbon footprint associated with rice production. By choosing equipment that utilizes advanced technologies, such as solar energy or heat recovery systems, farmers can optimize their drying processes while conserving resources.

Moreover, energy-efficient rice dryers often feature better insulation and improved airflow designs, which lead to more uniform drying and reduced drying times. This not only enhances the quality of the rice but also minimizes losses due to over-drying or under-drying, directly impacting the profitability of rice cultivation. Thus, investing in energy-efficient drying technology is a vital step for rice producers aiming to modernize their operations and ensure sustainable agricultural practices.

When selecting the best rice dryer to fit your budget, it’s crucial to understand the cost dynamics involved. Recently, budget considerations in various industries have shown that consumers are often torn between higher-end models and more affordable alternatives. For instance, similar to choosing between upper-tier electric vehicles and budget-friendly options, rice dryer buyers may find themselves weighing quality against price. Industry reports indicate that investing in a high-quality dryer can significantly enhance processing efficiency and reduce long-term operational costs. This is particularly relevant in agricultural contexts, where time and thoroughness can directly impact profit margins.

Furthermore, when comparing rice dryers, features such as capacity, energy consumption, and maintenance requirements should be scrutinized closely. According to market analysis, models that boast longer maintenance intervals and lower energy use often yield better overall value. For those operating within a specific budget, such as 300,000 units or less, focusing on essential features rather than brand name can lead to a more practical purchase decision. Understanding these financial facets ensures that farmers and producers can maximize their investments while effectively meeting their operational needs.