Leave Your Message

Choosing the right grain dryer is essential for successful farming. In the U.S., nearly 40% of harvested grain spoils due to improper drying. This statistic highlights the importance of reliable grain drying equipment. A good grain dryer prevents moisture damage and improves storage quality.

Farmers face various challenges in selecting a grain dryer. Different crops require specific moisture levels for optimal storage. For example, corn typically needs to be dried to 15% moisture. Additionally, the scale of farming operations influences the choice. A large operation may require a high-capacity dryer, while smaller farms might manage with less.

While many grain dryers offer advanced technology, not all are suitable for every farm. Farmers must consider their unique needs. Efficiency, cost, and capacity play a significant role in this decision. It's crucial to reflect on what features are actually necessary. Finding the right grain dryer can prevent losses and enhance profit margins.

When selecting a grain dryer, understanding the available types is crucial for farmers. The right choice often hinges on the scale of your operation. For small farms, batch dryers are a popular option. These dryers allow for flexibility and are usually more affordable. Many farmers in this category have reported efficiency improvements of up to 15% after switching to modern batch dryers.

In contrast, larger farming operations may benefit from continuous flow dryers. These systems can process grain at higher volumes, reducing the drying time significantly. Reports indicate that continuous flow dryers can handle up to 10 tons of grain per hour. However, they often come with higher initial costs and greater energy requirements. Farmers must weigh these factors carefully.

Climate conditions also play a role in dryer selection. For instance, humid areas may require more robust systems to prevent spoilage. Conversely, in drier regions, smaller units might suffice. Farmers have shared mixed experiences, sometimes regretting choices made without considering long-term impacts. A shift toward energy-efficient models is worth exploring. It’s not just about meeting immediate needs; it's about sustainability and future resilience in farming.

This bar chart illustrates the average dryer capacity in bushels per hour for different farming scales: small, medium, and large. Selecting the right grain dryer depends on your farming scale to ensure efficient grain drying.

When choosing a grain dryer, consider several key factors.

Capacity is paramount. Assess your farm's production volume.

A dryer that can't handle your yield could lead to delays. Efficiency is another crucial aspect.

Look for models that minimize energy consumption while maximizing output. This may save on costs over time.

Temperature control is vital. Different grains need specific drying temperatures.

Ensure the dryer provides flexibility for varied crops. Additionally, consider the drying method.

Continuous flow dryers can be faster but may require more maintenance.

Batch dryers might be easier to manage for smaller operations.

Don’t overlook the importance of portability.

A dryer that can be moved around may better suit changing farm needs.

Reflect on your budget. Investing in a more expensive model may yield better long-term results.

However, weigh that against your current financial situation. Sometimes, saving upfront costs can lead to higher expenses down the line.

Finding the right balance is essential. The right grain dryer can significantly impact your productivity and profitability. Choose wisely.

Grain moisture levels are crucial for effective drying. Knowing your grain’s moisture content helps you select the right equipment. Too much moisture can lead to spoilage. On the other hand, low moisture may result in unnecessary drying costs. Farmers should regularly test their grain for accurate moisture readings.

Understanding the specific needs of your crop is important. Different grains have varying moisture thresholds. For example, corn typically should be dried to 15% moisture. On the contrary, wheat needs about 13%. These requirements impact not only the drying process but also the storage conditions.

Equipment choices can also be overwhelming. Not all dryers are built for every type of grain. Some dryers may not adequately handle high moisture levels, leading to inefficiencies. It’s vital to consider both current and future needs. This choice could impact your harvest yield and overall profitability in unpredictable ways. Consider regular evaluations of your drying strategy as the seasons change.

When selecting a grain dryer, energy efficiency is crucial. An energy-efficient dryer can significantly reduce operating costs. It minimizes fuel consumption while maintaining optimal drying performance. Look for models with insulation and high-efficiency motors. These features can help save money over time.

Cost-effectiveness goes beyond the initial purchase price. Consider maintenance costs and energy use. Some dryers may be cheaper upfront, but higher energy bills add up. You might also want to evaluate drying capacity. If a dryer can't handle your harvest, it could become inefficient.

Understanding your specific needs is vital. Do you operate on a large scale or a smaller farm? Reflect on your capacity and energy sources. Your location's climate can also play a role. In some cases, a less powerful dryer might work better for smaller operations. Gather input from others in your farming community. Their experiences might highlight considerations you haven't thought of yet. Making an informed choice on grain dryers matters greatly for your bottom line.

| Dryer Type | Capacity (Bushels/hour) | Energy Source | Energy Efficiency (BTU/bushel) | Estimated Cost (USD) |

|---|---|---|---|---|

| Batch Dryer | 100 | Natural Gas | 35 | 15,000 |

| Continuous Flow Dryer | 200 | Propane | 30 | 25,000 |

| Mixed-Flow Dryer | 150 | Electricity | 28 | 20,000 |

| Heat Pump Dryer | 80 | Electricity | 25 | 30,000 |

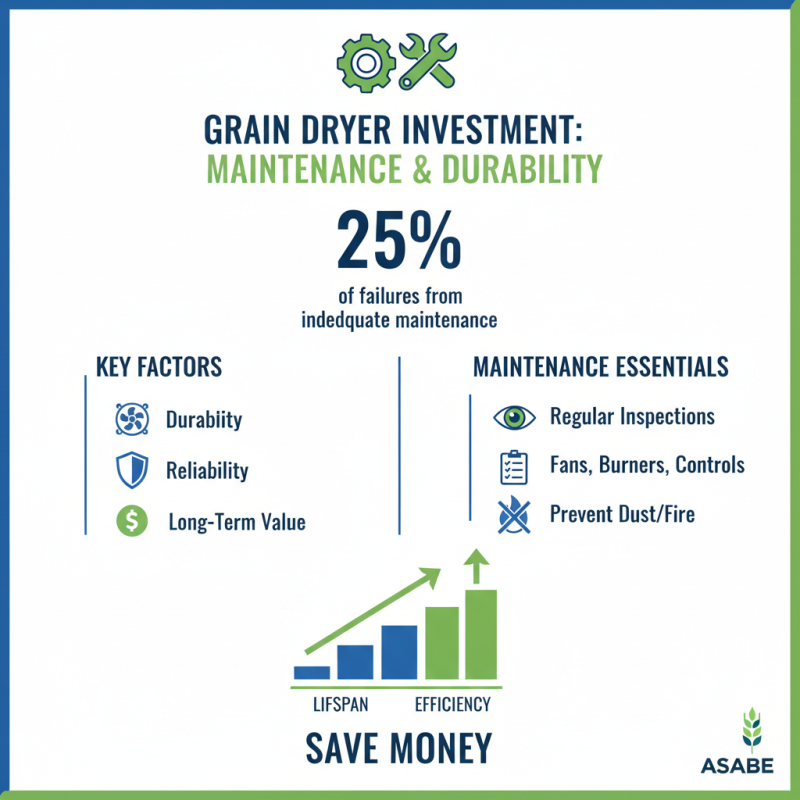

When selecting a grain dryer, maintenance and durability are key factors. Grain dryers can be significant investments. According to a survey by the American Society of Agricultural and Biological Engineers, nearly 25% of grain dryer failures stem from inadequate maintenance. Regular inspections are crucial. Components like fans, burners, and controls should be checked frequently. Dust accumulation can lead to reduced efficiency and risks of fire.

Longevity is often linked to the choice of materials. Dryers made from high-grade steel resist corrosion better than their lower-grade counterparts. Research suggests that drying systems tend to last longer with proper care. However, many farmers overlook simple tasks, like lubricating moving parts. This often leads to premature wear. A grain dryer that functions well should serve effectively for 15 to 20 years with diligent maintenance.

Considering that grain prices can fluctuate, investing in maintenance pays dividends. According to industry data, up to 30% can be saved on operational costs through efficient machinery care. Therefore, making maintenance a priority can enhance dryer performance and longevity. Regularly scheduled servicing helps identify potential issues early. This not only ensures durability but also maximizes grain quality during storage.