Leave Your Message

Choosing the right Grain Dryer for your farm in 2026 is crucial. The right dryer can enhance harvest efficiency and safeguard crop quality. According to the USDA, over 90% of U.S. farms rely on effective grain drying methods. Professionals in the field emphasize the importance of selecting a dryer that fits specific operational needs.

"Selecting the right equipment can make or break a harvest," says John Smith, a leading expert in agricultural equipment. The market for Grain Dryers is expected to grow significantly, driven by the increased demand for quality grains. However, making the right choice isn't easy; many farmers overlook key performance metrics.

Investing in the latest technology may feel daunting. High initial costs and rapidly changing technology present challenges. Yet, advancements in energy efficiency and automation can lead to long-term savings. Understanding your unique requirements can help navigate these complexities, ensuring you choose the best Grain Dryer for your farm. Balancing budget constraints with innovative features is essential in this evolving landscape.

When selecting a grain dryer for your farm, several factors come into play. The capacity of the dryer must align with your production volume. Knowing your harvest size is crucial. If you underestimate this, you may face delays.

Efficiency is another key aspect. Look for dryers that balance speed and energy consumption. A fast dryer can save time, but high energy use can raise costs.

Tips: Always consider the climate. If you live in a humid area, a more robust dryer may be necessary. Think about noise levels too. Grain dryers can be loud, which can irritate your neighbors or disrupt farm operations.

The ease of maintenance is important as well. A complicated system might lead to issues down the road. Regular upkeep is often neglected. A user-friendly design simplifies routine check-ups. Take the time to assess your long-term needs. Investing in a dryer that meets your requirements now can prevent future headaches.

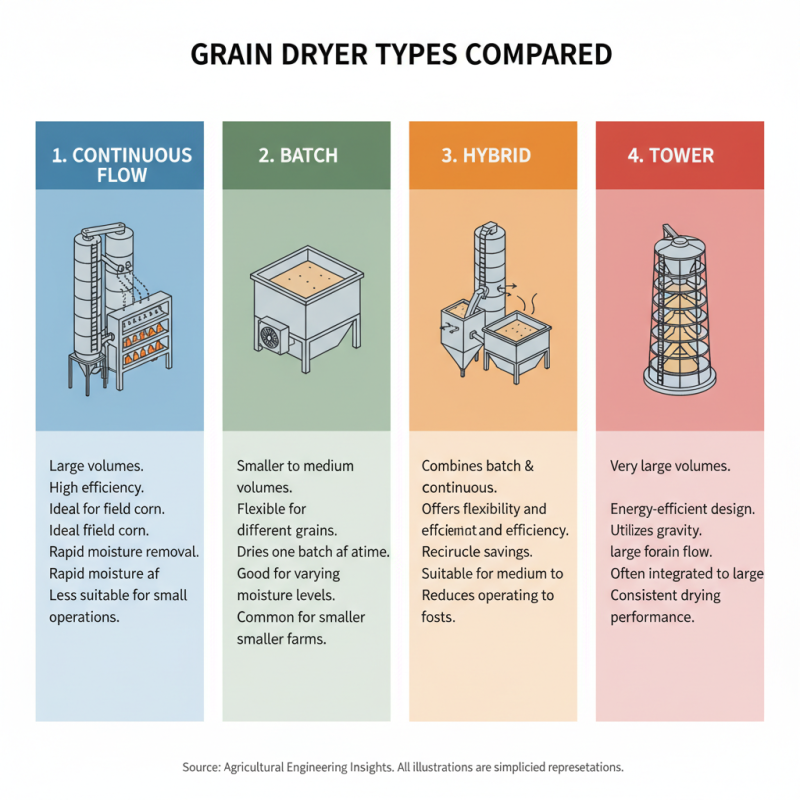

When selecting a grain dryer, understanding the types available is crucial. There are primarily four categories: continuous flow, batch, hybrid, and tower dryers. Continuous flow dryers are efficient for large volumes, often used for field corn. They can handle moisture removal rapidly, but they may not suit smaller operations.

Batch dryers are ideal for diverse grains, offering flexibility. However, they require manual loading and unloading, leading to labor costs. Hybrid dryers combine features of both continuous and batch systems, allowing adaptability for various grain types. For instance, soybeans and wheat may thrive in these setups, as they balance efficiency and care in drying.

It's essential to consider moisture retention in grains. Research indicates that improper drying can cause up to 20% loss in quality. Grain types respond differently, so it’s imperative to select a dryer that suits your specific needs. This mismatch can lead to spoilage and economic loss. Regular maintenance is often overlooked but crucial for efficient operation. Assess which grain you handle most frequently and research dryer options accordingly. Making a hasty decision can result in significant issues down the line.

When choosing a grain dryer, capacity and efficiency are critical. The right dryer can mean the difference between a profitable harvest and significant losses. In 2026, many farmers are considering dryers with varying capacities. For instance, a dryer that handles 200 to 400 bushels per hour may suit small to medium farms, while larger operations might need 1,000 bushels per hour or more. The increased capacity can significantly reduce drying times.

Energy efficiency is another major factor. According to industry data, about 35% of operating costs come from energy consumption in grain drying. Modern dryers employ advanced technologies that reduce energy use while maximizing performance. Reports indicate that some new models can achieve efficiencies of up to 30% better than older designs. This efficiency helps farmers save money and minimize their environmental impact, yet some still overlook these advancements.

It's also important to consider your specific needs. Seasonal weather variations can impact grain moisture levels, making it essential to choose a dryer capable of adapting to different conditions. Some dryers may excel in certain climates but fail in others. Regular maintenance is often neglected, leading to reduced efficiency over time. Reflecting on these aspects before making a decision can lead to a more suitable choice for your farm's unique requirements.

| Model | Capacity (Bushels) | Drying Efficiency (%) | Fuel Type | Price ($) |

|---|---|---|---|---|

| Model A | 1500 | 90 | Propane | 25,000 |

| Model B | 2000 | 85 | Natural Gas | 30,000 |

| Model C | 2500 | 92 | Electric | 40,000 |

| Model D | 1800 | 88 | Diesel | 28,500 |

| Model E | 2200 | 87 | Biomass | 35,000 |

When evaluating grain dryers for cost-effectiveness and energy efficiency, farmers must consider several key factors. According to data from the American Society of Agricultural and Biological Engineers, approximately 15-20% of harvested grain can be damaged by improper drying. This makes investing in the right equipment crucial. The average cost of grain drying can range from $0.03 to $0.08 per bushel, depending on the technology used. A thorough analysis of energy consumption can lead to substantial savings over time.

Energy efficiency is vital for long-term sustainability. Recent studies indicate that high-efficiency dryers can reduce energy use by up to 30% compared to older models. However, not all farmers can afford the latest technologies. Some may need to weigh upfront costs against future savings. This decision can be tricky. It’s important to examine local energy rates and dryer performance data to make an informed choice. Sometimes, lower initial costs can mask poor efficiency, leading to higher bills down the line.

More advanced systems might seem appealing, but their complexity can lead to operational challenges. Maintenance costs can also rise if parts are difficult to source. Builders often overlook these aspects. Farmers should measure their grain drying needs against potential energy costs and available technology. Each choice has trade-offs that can affect overall profitability. A careful approach is essential.

When selecting a grain dryer, maintenance should be a priority. Regular upkeep ensures efficiency and longevity. Simple tasks can make a big difference. Check for dust buildup often. Clean filters regularly to keep airflow strong. A faulty dryer can lead to crop loss, which is devastating.

Support options are also crucial. Look for suppliers that offer comprehensive after-sales services. Understand the warranty details. Knowing how and where to get help is essential. In rural areas, quick support can be hard to find. Building a relationship with local technicians may prove beneficial.

Consider scheduling routine check-ups. Plan these visits around your harvest cycle. However, not all maintenance needs are clear-cut. Sometimes issues pop up unexpectedly. Being proactive can minimize costly breakdowns. It’s vital to stay informed about new technologies and maintenance techniques as well. Embrace learning; it can prevent regrets later.