Leave Your Message

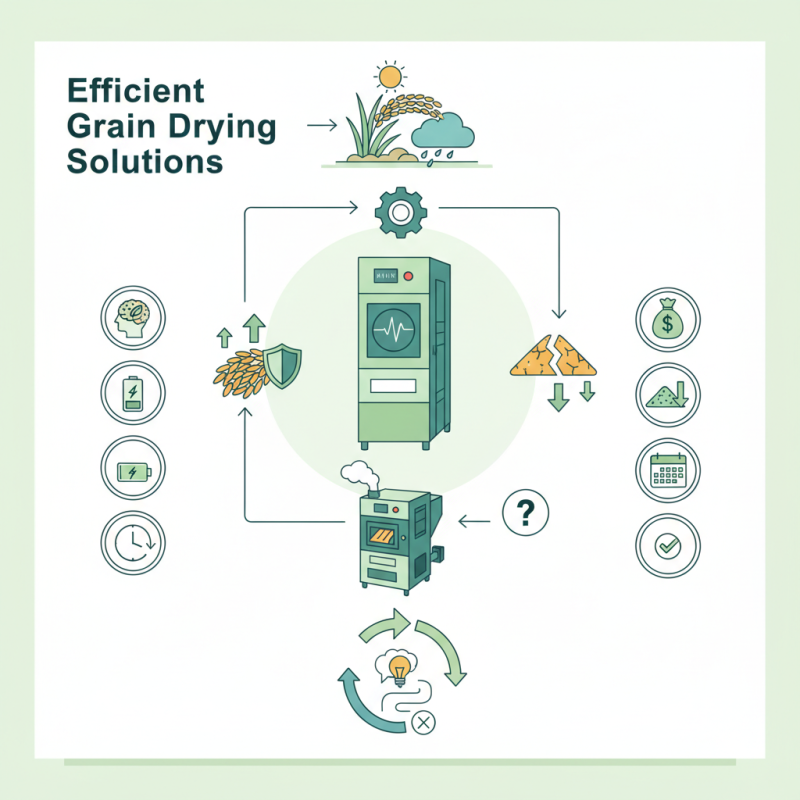

In the world of agriculture, choosing the right Rice Dryer is crucial. Efficient grain drying solutions can significantly impact yield and quality. As rice production often meets uncertain weather conditions, reliable equipment becomes vital.

Modern Rice Dryers offer various features. Some use advanced technology, optimizing energy consumption while ensuring uniform drying. Others may compromise efficiency for lower costs. It's essential to weigh these options carefully.

Farmers should consider their specific needs. A well-chosen Rice Dryer can save time and reduce losses. However, it requires attention to detail and informed decisions. Reflecting on past choices can lead to better future outcomes.

The landscape of grain drying technology is evolving. Rice dryers are becoming critical for ensuring high-quality harvests. Efficient grain drying prevents spoilage and maintains nutritional value. When selecting a rice dryer, various factors come into play. Capacity, energy consumption, and drying time must be considered.

Many farmers often overlook the importance of proper airflow. Insufficient airflow can lead to uneven drying, causing quality issues. Some dryers may boast capacity, but if they lack effective designs, performance suffers. It's not just about speed; efficiency holds significant weight. Evaluating fuel sources and energy efficiency is crucial for long-term cost-effectiveness.

Innovation is key in this sector. Some new models incorporate advanced sensors for monitoring moisture levels. This technology helps achieve optimal drying conditions. However, users must be cautious with calibration. Misunderstanding these settings may lead to inadequate drying and grain loss. Continuous improvement is essential for achieving successful outcomes in grain drying.

Choosing the right rice dryer is essential for optimizing grain drying. Several factors come into play, such as capacity, energy efficiency, and drying method. The dryer should meet your specific needs regarding the volume of rice processed. Knowing how much rice you usually harvest will help you pick an adequate model.

Energy efficiency is crucial. Dryers can consume a lot of power. Look for models that minimize energy use while maintaining performance. If a dryer operates well but costs too much in energy, it might not be the best choice. Also, consider the drying method—whether it’s hot air, vacuum, or another technology. Each has pros and cons.

Tips: Always compare different models before buying. Check user reviews for real-world insights. Keep in mind that a cheaper model could lead to higher costs in the long run due to inefficiency. Even the best dryers can have quirks. You might have to adapt your process. Monitor the performance regularly; if it's not meeting expectations, re-evaluate your choice.

When it comes to drying rice, selecting the right dryer can make a significant difference. Efficient grain drying solutions are vital for preserving quality. A good dryer should effectively reduce moisture levels while preventing grain damage. Many models come with features like adjustable temperatures and airflow control. These allow users to customize settings to suit different rice varieties.

Top brands often showcase reliability in performance, but it's essential to evaluate each model carefully. Some units may require more maintenance than anticipated. It’s worth noting that energy efficiency can vary widely among different dryers. Some might be cost-effective upfront but lead to higher bills down the line. Additionally, user feedback is crucial. Sometimes, what looks good on paper may fall short in real-world applications.

Incorporating advanced drying technology is another trend. These innovations aim to speed up the drying process while preserving essential nutrients. However, understanding the underlying mechanics can be challenging. Users may overlook how temperature fluctuations affect grain integrity. Thorough research and careful consideration of available features can help ensure a worthwhile investment.

| Model | Drying Capacity (kg/h) | Energy Consumption (kW) | Drying Time (hours) | Features |

|---|---|---|---|---|

| Model A | 100 | 15 | 4 | Automatic Control, Energy Efficient |

| Model B | 150 | 20 | 3.5 | High Efficiency, Compact Design |

| Model C | 200 | 25 | 5 | Digital Display, Multi-functional |

| Model D | 120 | 18 | 4.5 | Portable, User-friendly Control |

| Model E | 180 | 22 | 3 | Low Noise, Fast Drying |

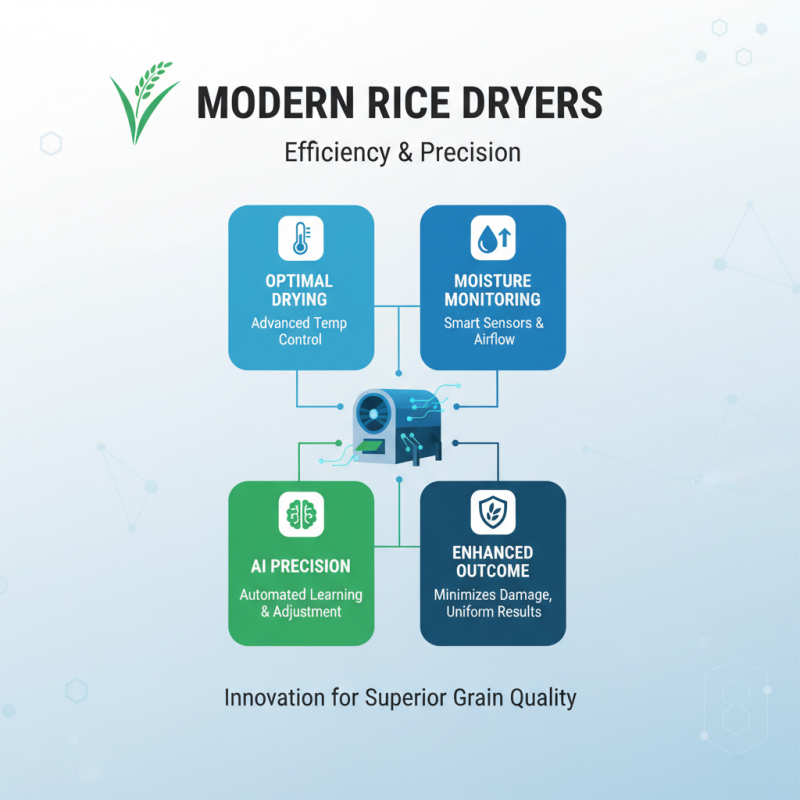

Modern rice dryers are equipped with innovative features that enhance efficiency and effectiveness. Advanced temperature control systems help maintain optimal drying conditions. Sensors monitor moisture levels closely, adjusting airflow as needed. Some models even use AI technology for precision drying. This innovation minimizes grain damage and ensures uniform results.

Energy efficiency is another vital aspect. Many dryers now utilize renewable energy sources or optimized heating systems. This not only reduces operational costs but also decreases environmental impact. However, the initial investment can be high. Farmers may hesitate, weighing long-term savings against upfront expenses.

Moreover, user-friendly interfaces simplify operations. Farmers can easily set and monitor drying cycles. Yet, technology can be intimidating for some. Training may be necessary to fully utilize these advanced machines. Continuous learning and adaptation are essential in this evolving field.

Maintaining rice dryers is crucial for optimal performance. Regular maintenance can enhance efficiency and extend service life. According to a study by the Agricultural Machinery Association, proper upkeep can improve efficiency by up to 20%. This results in reducing energy consumption, which can lead to considerable savings over time.

Daily checks can make a significant difference. Inspecting belts, fans, and electrical connections should be routine. Cleaning dust and debris from the dryer can prevent overheating. Inadequate maintenance may lead to breakdowns, which can be costly. On average, repair costs can reach up to 15% of the initial investment in a dryer system.

It’s essential to schedule annual professional inspections. These checks help identify potential issues early. However, many operators overlook this step. Ignoring it can shorten the dryer’s lifespan significantly. Treating maintenance as a priority rather than an afterthought can protect your investment. Regular upkeep pays off in efficiency and durability.