Leave Your Message

In the realm of food preservation, the Dried Fruit Dryer stands out as a vital tool for enthusiasts and businesses alike. As technology advances, innovations in this industry are crucial. Expert Tony Fielder once said, "Embracing new dryer technologies can enhance flavors and extend shelf life." This statement underscores the importance of integrating modern features into traditional methods.

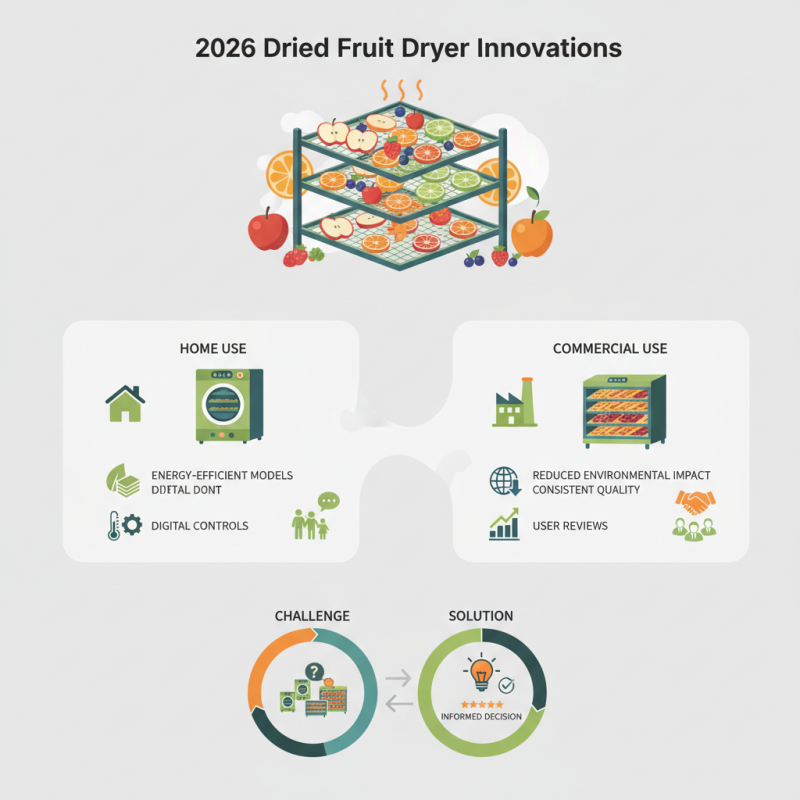

Home and commercial users can benefit significantly from these innovations. For instance, users now demand energy-efficient models. These models not only save money but also reduce environmental impact. Some dryers include digital controls for precise temperature settings. This ensures consistent results, which is essential for preserving fruit quality.

However, the journey to optimal drying isn't without challenges. Selecting the right Dried Fruit Dryer can be overwhelming. With numerous brands offering various features, it can lead to confusion. Many consumers overlook the importance of user reviews, which provide insights on performance. Taking time to research can ultimately make a big difference. Embracing this knowledge will empower users to make informed decisions in this evolving market.

As we move towards 2026, innovations in dried fruit dryers are transforming home and commercial food preservation. Users increasingly demand energy-efficient designs. Many new units feature smart technology, allowing temperature and humidity control from a mobile app. This means enhanced convenience and reduced energy waste.

Emerging trends highlight sustainability in materials and operations. Renewable energy sources are being integrated into dryer designs. This approach not only lowers carbon footprints but also appeals to eco-conscious consumers. Additionally, brands are exploring biodegradable components. These updates, while innovative, also present challenges in sourcing eco-friendly materials.

Customization options are another focus for 2026. Consumers want dryers tailored to specific fruits or vegetables. This shift raises questions about standardization and usability. Balancing diversity and ease of use remains a complex task for manufacturers. The pathway forward includes both exciting advancements and significant hurdles.

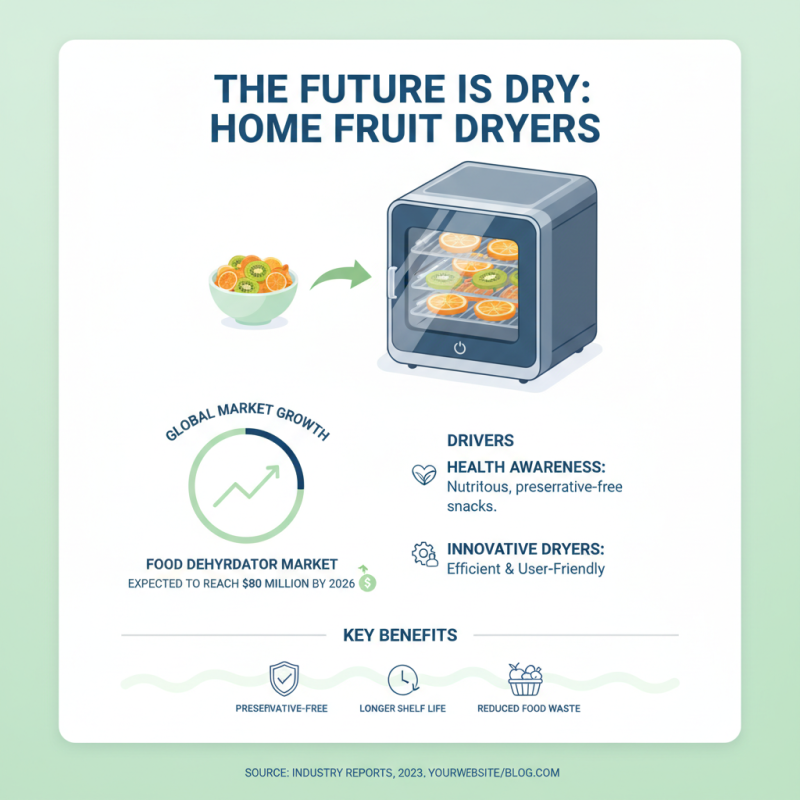

Innovative home dried fruit dryers are gaining attention for their efficiency and user-friendly features. Recent industry reports indicate that the global food dehydrator market is expected to reach $80 million by 2026. This growth is driven by rising health consciousness. People want nutritious snacks without preservatives.

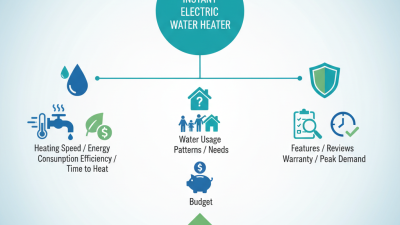

Key features of these dryers include adjustable temperature settings and timer functions. Users can set precise conditions for different fruits. Some models even have digital displays for easy monitoring. The ability to dry fruits evenly is crucial. Uneven drying can lead to spoilage. Data from the Food and Nutrition Journal shows that proper dehydration retains up to 90% of fruits' vitamins.

Features like built-in filters and noise reduction are also important. Many consumers prefer quieter machines for home use. Portable designs enable easy storage and movement. However, some units can be heavy, making them less convenient. As the industry grows, potential buyers should weigh the benefits against these practical challenges.

Innovations in commercial dried fruit dryers are reshaping the industry. These machines now feature advanced energy-efficient technology. This helps businesses reduce costs significantly. Moreover, their scalability allows for various production sizes. From small businesses to large manufacturers, dryers cater to all needs.

Automation is another key improvement. Many new models can operate with minimal human intervention. Users can set parameters and monitor the drying process remotely. However, reliance on technology can pose challenges. Equipment failures can disrupt production. Manual checks are still essential to ensure the quality of dried fruits.

Durability and maintenance aspects deserve attention too. Improved materials enhance the longevity of these dryers. Yet, regular upkeep can be cumbersome. Businesses often overlook this aspect in favor of higher output. Striking a balance between efficiency and care is crucial. Maintaining equipment can prevent downtime and extend lifespan, but it requires commitment.

The production of dried fruit dryers has increasingly focused on sustainability. Research shows that global dryer production generates significant waste. In fact, up to 30% of materials often go unutilized. This inefficiency raises concerns about resource management. Manufacturers are exploring eco-friendly materials and methods. These advancements could lead to reduced carbon footprints.

Energy consumption in dryer operation is another key issue. Reports indicate that traditional models often use excessive electricity. Recent innovations aim to minimize energy use by 25%. This reduction benefits both the environment and operational costs. However, some designs require further improvement. Efficiency can vary significantly based on the dryer type and design.

Finally, water usage during the drying process merits attention. Many current systems lack efficient water reclamation. Studies highlight that up to 50% of water is wasted. Innovations incorporating reclaim systems could drastically improve this. Yet, many manufacturers hesitate to invest in new technologies. Initiatives promoting sustainable practices are essential for the industry's future. Addressing these challenges is vital for a greener approach in both home and commercial applications.

This chart displays the innovations in dried fruit dryers for 2026, focusing on key factors such as energy efficiency, sustainability, speed of drying, user-friendliness, and size/portability. Each factor is rated on a scale of 1 to 10, showcasing the advancements in technology for both home and commercial use.

When comparing home and commercial dried fruit dryers, several key differences emerge. Home models are usually compact. They cater to small batches. Users often seek convenience and ease of use. Meanwhile, commercial dryers are larger. They handle significant volumes of fruit. These machines often feature advanced technology for consistent results.

One notable innovation in home dryers is energy efficiency. Many new models use less energy while maintaining performance. This is a win for eco-conscious users. However, they may not dry fruit as quickly as commercial dryers, which often have larger heating elements. The high capacity of commercial units can produce a uniform drying result that home units struggle to match.

**Tips:** Choose a home dryer that has adjustable temperature settings. This allows for better control over the drying process. For commercial use, consider those with programmable features. They can optimize time and reduce labor. Pay attention to maintenance needs—some machines are easier to clean than others.

| Feature | Home Dried Fruit Dryer | Commercial Dried Fruit Dryer |

|---|---|---|

| Capacity (kg/batch) | 1-5 kg | 20-100 kg |

| Drying Technology | Convection | Infrared / Vacuum |

| Energy Source | Electric | Gas / Electric |

| Temperature Range (°C) | 35-70°C | 25-85°C |

| Automation Level | Manual / Basic | Fully Automated |

| Drying Cycle Time (hours) | 6-12 hours | 3-6 hours |

| Cost ($) | 100-500 | 2000-10000 |

| Suitable for | Home Use | Commercial Production |